Model based fault detection lab

Model Based Fault Detection (MBFD) is a technique that identifies Faultthrough-out the rotor system by using different mathematical fault models . MBFD is one of the technique which comes under Condition monitoring and Fault diagnosis.Before going to the detail of MBFD let us get acquianted to Condition monitoring and fault diagnosis.

Condition Monitoring And Fault Diagnosis ::

Condition monitoring is the process of monitoring a parameter of condition in machinery, such that a significant change is indicative of a developing failure. It is a major component of predictive maintenance. The use of conditional monitoring allows maintenance to be scheduled, or other actions to be taken to avoid the consequences of failure, before the failure occurs. Before going to the detail of condition monitoring let us understand the fault and its related terms.

A fault is when the structure can no longer operate satisfactorily. If one defines the quality of a structure or system as its fitness for purpose or its ability to meet customer or user requirements, it suffices to define a fault as a change in the system that produces an unacceptable reduction in quality.

• Damage is when the structure is no longer operating in it’s ideal condition but can still function satisfactorily, i.e. in a sub-optimal manner

• A defect is inherent in the material and statistically all materials will contain some unknown amount of defects; this means that the structure can operate at its design condition if the constituent materials contain defects.

Hidden Div

The above notation allows a hierarchical relationship to be developed; i.e., defects lead to damage and damage leads to faults. Using this idea it is possible to design a damage tolerant structure. In order to obtain a damage tolerant structure it is necessary to introduce monitoring systems, so that one can decide when the structure is no longer operating in a satisfactory manner.

In machine condition monitoring, the fundamental requirement is to detect the damage. Often, in monitoring a machine, the location is not an issue. Machines are largely heterogeneous structures and each of the critical components will usually be subject to different failure mechanisms; the damage types are different for each component e.g. bearings, gearboxes, rotors. This means that effective damage classification usually also amounts to effective location; often each important component will be individually given a sensor. Another aspect of machine monitoring is that the many of the components will be low-cost items. This means that it is economic to replace them at the first sign of damage. This in turns means less emphasis on estimating the severity of the damage or determining the remaining safe-life, although residual-life studies exist.

Fault diagnosis in rotating machinery

The subject of the fault diagnosis is rotating machinery is vast, including the diagnosis of items such as rotating shafts, gears and pumps. The different types of faults that are observed in these areas and the methods of their diagnosis are accordingly great, including vibration analysis, model-based techniques, and statistical analysis.

Modern condition monitoring techniques encompass many different themes, one of the most important and informative being the vibration analysis of rotating machinery- a topic that has prompted much research to be carried out and a corresponding amount of literature to be produced. Using vibration analysis, state of a machine can be constantly monitored, and detailed analyses may be made concerning the health of the machine and any fault that may be arising or have arisen, serious or otherwise. Common rotor-dynamic faults include self-exited vibration due to system instability and more often, vibration due to some externally applied load, such as cracked or bent shaft and mass unbalance. |

Model based fault detection

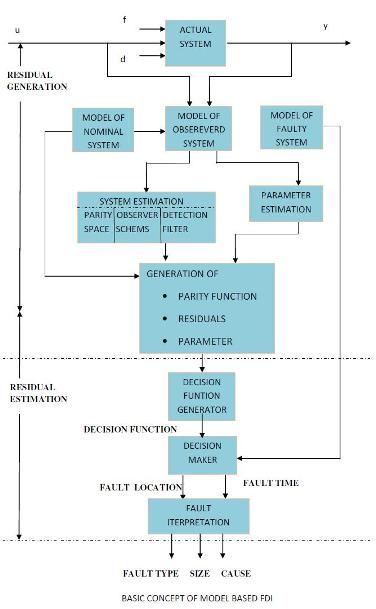

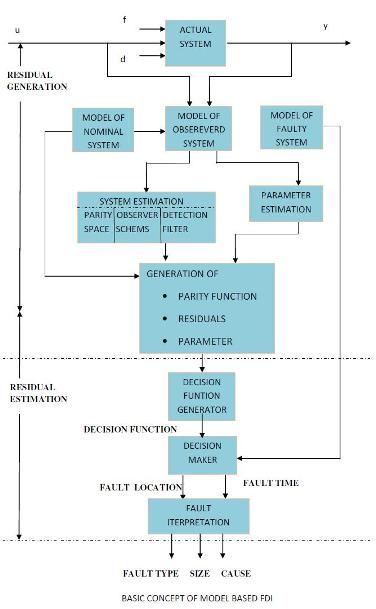

Different approaches for fault detection using mathematical models have been developed. The task consists of the detection of faults in the processes, actuators and sensors by using the dependencies between different measurable signals. These dependencies are expressed by mathematical process models. Figure shows the basic structure of model-based fault detection.

Hidden Div1

This method gives more exact and faster information about the state compared to the conventional signal based system since a priori information of the system is included systematically in the identification process. Therefore the type, location and extent of fault can be estimated more reliably, in most cases, without stopping the machine.

For implementing any model based technique, one has to have a trustworthy mathematical model of the system as well as of the possible faults. Conventionally, these mathematical models can be non-linear because of non-linearities due to faults or system properties. The approach discussed here avoids the no-linearities in the system equations which are normally brought by the existence of the fault.

The technique takes into account the fault induced change of the rotor system by so-called Equivalent loads. Equivalent loads are virtual forces and moments acting on the linear undamaged system model to generate the dynamic behaviour of the damaged non-linear system. The system’s non-linearity is described by these equivalent loads which are function of the type, position and extent of fault. Thus, the originally linear system equations remain linear even when non-linear faults are present. The equivalent loads calculated from the measured data are then compared with the equivalent loads obtained from fault models. |