•To demonstrate robot trajectory planning and programming of a robot manipulator

• To demonstrate machine loading /unloading by using robot

Robot

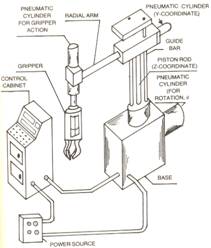

An industrial robot is a reprogrammable, multifunctional manipulator designed to move material, parts, tools or other specialized devices through various programmed motions for the performance of a variety of tasks. It is reprogrammable in the sense that, when interfaced with a computer or a microprocessor, it can be edited to have a new program and information. It is multifunctional in the sense of its versatility i.e. it can perform various activities e.g. it can use an end effector to move materials and parts, it can actuate tools like painting gun for spray painting, welding gun for welding or assemble components of a part. The robot has a mechanical configuration called the manipulator arm with a gripper or end-effector at its free end to move from point to point or in a continuous path following some trajectory.

The components of a robot include:

- A base – fixed or mobile

- A manipulator arm with several degrees of freedom (DOF)

- An end-effector or gripper holding a part or a tool

- Drives or actuators causing the manipulator arm or end-effector to move in space

- Controller with hardware and software support for giving commands to the drives

- Sensors to feed back the information for subsequent actions of the arm or gripper as well as to interact with the environment in which the robot is working

- Interfaces connecting the robotic subsystems to the external equipment in the outside world

Robot Programming

The robot manipulator can move its arm, wrist or gripper to the desired position describing a definite path.The figure below shows a Scorbot robot manipulator having five axes. Out of the five axes, the first three axes namely, wrist, shoulder and elbow constitute the body of the manipulator and are necessary to place the gripper of the robot at a definite location within the work envelope. The remaining two axes namely, the wrist pitch and the wrist rollare used to orient the gripper.

<insert video of robot joints moving>

The robot can be moved by using push buttons on a teach pendant box or automatically under some form of program control. Programming for generation of the path of a robot manipulator can be accomplished by various ways and this path is controlled by the robot controller by two methods:

- Point-to-point (PTP) control

- Continuous path (CP) control

Point-to-point (PTP) control

In the PTP programming method, the robot arm is taught to move from a point to another in its work envelope. Once the robot arm has been moved to a particular point by using the teach pendent, the locational point is recorded into the robot's memory in the control by the programmer by pushing a 'record' button on the teach pendent. Next the robot arm is moved to a second point and this new point or position is recorded again by pushing the record button. This method is known as teaching. Thus, the point-to-point path generation in steps is done in the 'teach' mode. In 'auto' mode, all the points so recorded are played back and the robot arm starting from its first point moves through the programmed points till it reaches the end point. Figure below shows a PTP controlled path.

PTP control does not control the path taken by the robot to move from one point to the next. Control of the sequence of positions is adequate for certain applications like loading and unloading machines and spot welding.

In Continuous Path (CP) control, the path followed by the robot is controlled. In Continuous path motion, the discrete points programmed earlier may be traversed in a straight line or following a curve or an arc of a circle between the taught points as illustrated in Figure below. This is usually accomplished by making the robot move though a series of closely spaced points which describe the desired path. The individual points are defined by the controller rather than the programmer. When the program is on playback mode, the robot moves continuously through the points. Continuous path control is required for applications such as deburring, spray painting and arc welding.

Different robot programming languages are available for programming and control of the motions of robots.The robot programming language used for programming and control of the Scorbot robot that is used in this training program is Scorbase.

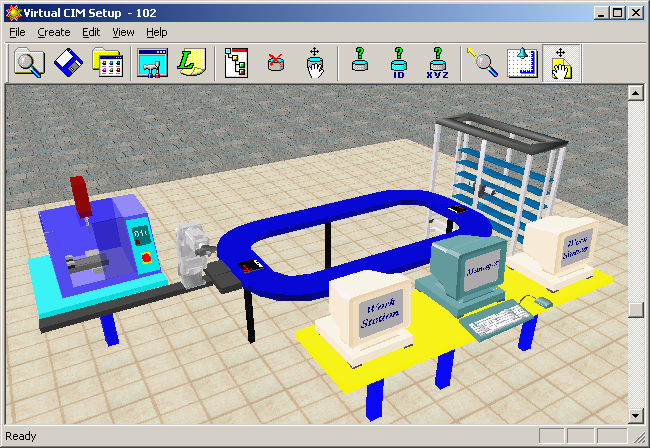

The set-up consists of the following

• 5-axis Robot manipulator with pneumatic gripper (For details, visit the Lab Facilities page by clicking here)

•Software for programming and control of robot (For details, visit the Lab Facilities page by clicking here)

•Software for simulation of robot

For more details on the above please visit the Lab Facilities page by clicking Here

1.Send us an e-mail at cimlab.iitkgp@gmail.com for obtaining an enrollment key .

2. Once you have received your enrollment key, go the website by clicking here .

For remote experimentation, please book a slot in advance.

Click here to view the available slots.

Click here for live video streaming of the experiment