Software for control and programming of robot manipulator ![]()

|

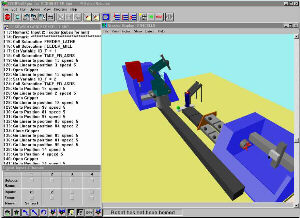

The software for control and programming of robot manipulator is Scorbase,which is a Windows based robot programming language used with Scorbot robot. A screenshot of Scorbase is shown above.

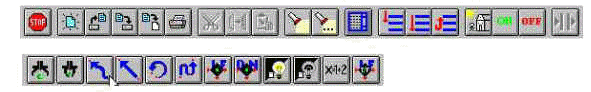

It provides a menu driven structure. It has a menu bar containing icons for different commands such as home, go to position, go linear to position, open gripper, close gripper, turn on output, run single cycle, run continuously, etc.as shown below.

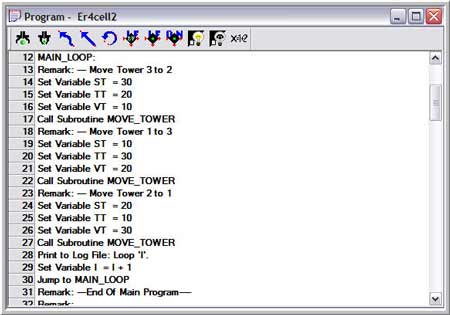

Scorbase further provides an Edit Window in which the editing of a new program can be executed as shown below.

Scorbase further provides an Edit Window in which the editing of a new program can be executed as shown below.

In Scorbase, various Windows editing features, such as insert line, delete line, etc, are available.

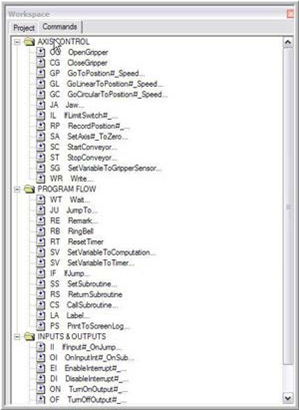

It further contains different commands to control the robot arm and peripherals (such as go to position, close gripper, open gripper, etc), various program flow commands (such as wait X seconds, set variable, set and call subroutine, etc), as well as commands to control the robot's peripherals via inputs and outputs (turn on/off output, if input on jump, set analog output, etc).

Scorbase provides a Command List Window as shown below containing a list of all the above commands. Clicking on the icons of the desired commands from the command list opens that command in the edit window. Each command in the command list can be also initiated by using various function keys.

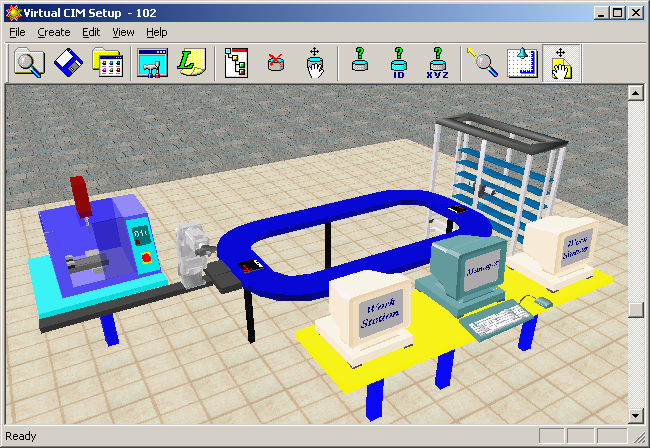

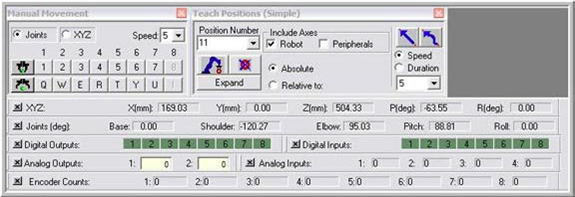

Scorbase offers different methods to enable teaching of the robot’s positions through a set of windows that are provided with various clickable icons as shown in the figure below:

1. On-line manual movement of the robot to the desired location and recording it as a position. This position is assigned either a number or a name.

2. Off-line positions recording - in offline mode positions can be taught and recorded by indicating their X Y Z value, or by teaching positions relative to absolute positions, etc. This window also enables the robot to be sent to the various recorded positions, thus enabling the user to check the validity of these positions prior to the execution of the complete program.

For more details,click here to refer to the user guide on robot programming using Scorbase.

The following are detailed specifications of Scorbase Robot program

| Communication with the robot controller over USB channel. |

| Full support and real time status display of robot,gripper and peripheral. |

| Scorbase program run time position manipulation. |

| Interrupt programming for handling responses to changes in digital input status. |

| The Cartesian Coordinate System(X,Y,Z,Pitch,Roll)is also used. |

| Visual Basic Script language integration to realize. |

| Extensive Variable Programming. |

| Multitasking capability with 100 concurrent running programs. |

| Saving and loading projects. |

The instruction in this page are for Scorbase only. If Robocell software is used go to here

The following are detailed specifications of the cnc milling machine

Power |

1 hp, 746W |

Motor type |

1 hp, 746W DC permanent magnet |

| Speed range | 0-3000 RPM |

| Throat | 5.5" (139 mm) |

Axis Travel |

X axis: 304 mm |

Feed rate |

2-1905 mm/min |

| Rapid traverse | 1905 mm/min |

| Stepper motors | 97 Ncm, 200 steps/rev |

| Nickel-plated table | 436 mm x 127 mm |

Repeatability: |

0.0127 mm |

| Resolution 1/2 step: | 0.0032 mm |