Objectives

The objective of this experiment is to detect fault in a material using ultrasonics waves.

Introduction

Ultrasonics Waves

Ultrasonics waves are the sound waves having frequencies over 20,000 Hz which are beyond the range of human hearing. Ultrasonics waves can be used to detect faults and gaps in the material.

Working of Ultrasonics

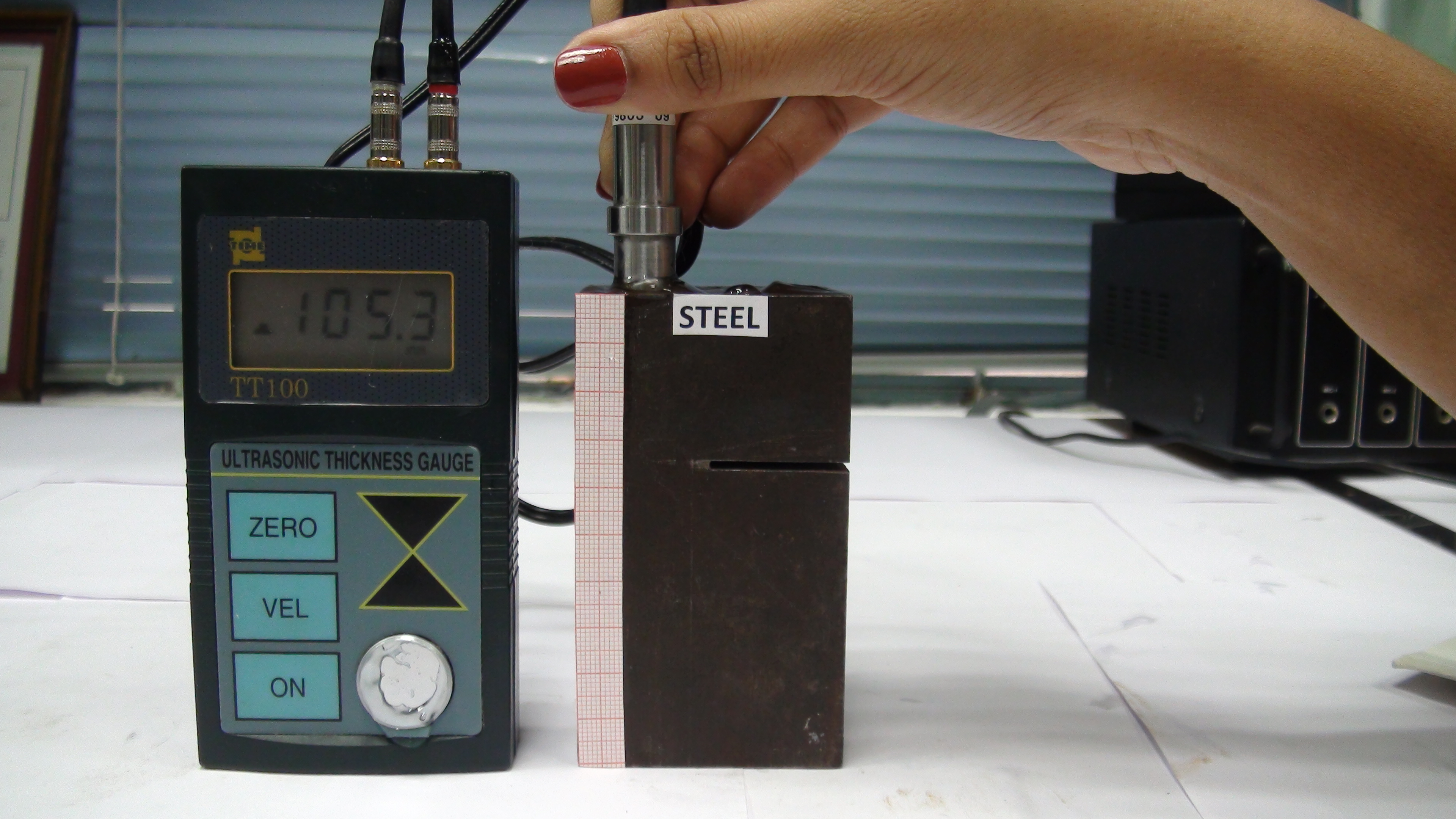

In ultrasonics testing, an ultrasound transducer connected to a diagnostic machine is passed over the object being inspected. The transducer is typically separated from the test object by a couplant (such as oil) or by water, as in immersion testing.

There are two methods of receiving the ultrasound waveform, reflection and attenuation.

Reflection (or pulse-echo) mode: The transducer performs both the sending and the receiving of the pulsed waves as the "sound" is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude representing the intensity of the reflection and the distance, representing the arrival time of the reflection.

Attenuation (or through-transmission) mode: A transmitter sends ultrasound through one surface, and a separate receiver detects the amount that has reached it on another surface after traveling through the medium. Imperfections or other conditions in the space between the transmitter and receiver reduce the amount of sound transmitted, thus revealing their presence. Using the couplant increases the efficiency of the process by reducing the losses in the ultrasonics wave energy due to separation between the surfaces.