Experimental study

Ultrasonics Thickness Gauge

It is the testing meter designed for measuring the thickness of material (metal, plastic, glass and any other good ultrasonics wave conductor) having two parallel surfaces on the top and bottom.

1. Main machine

2. Probe

3. Coupling agent

Working Principle of Ultrasonics Thickness Gauge

The ultrasonics wave pulses transmitted by the probe reach the object to be measured and propagate in the object and when they reach the interfaces, they are reflected back. The thickness of object is determined by precisely measuring the time the ultrasonics wave travels in the object.

Experimental Procedure

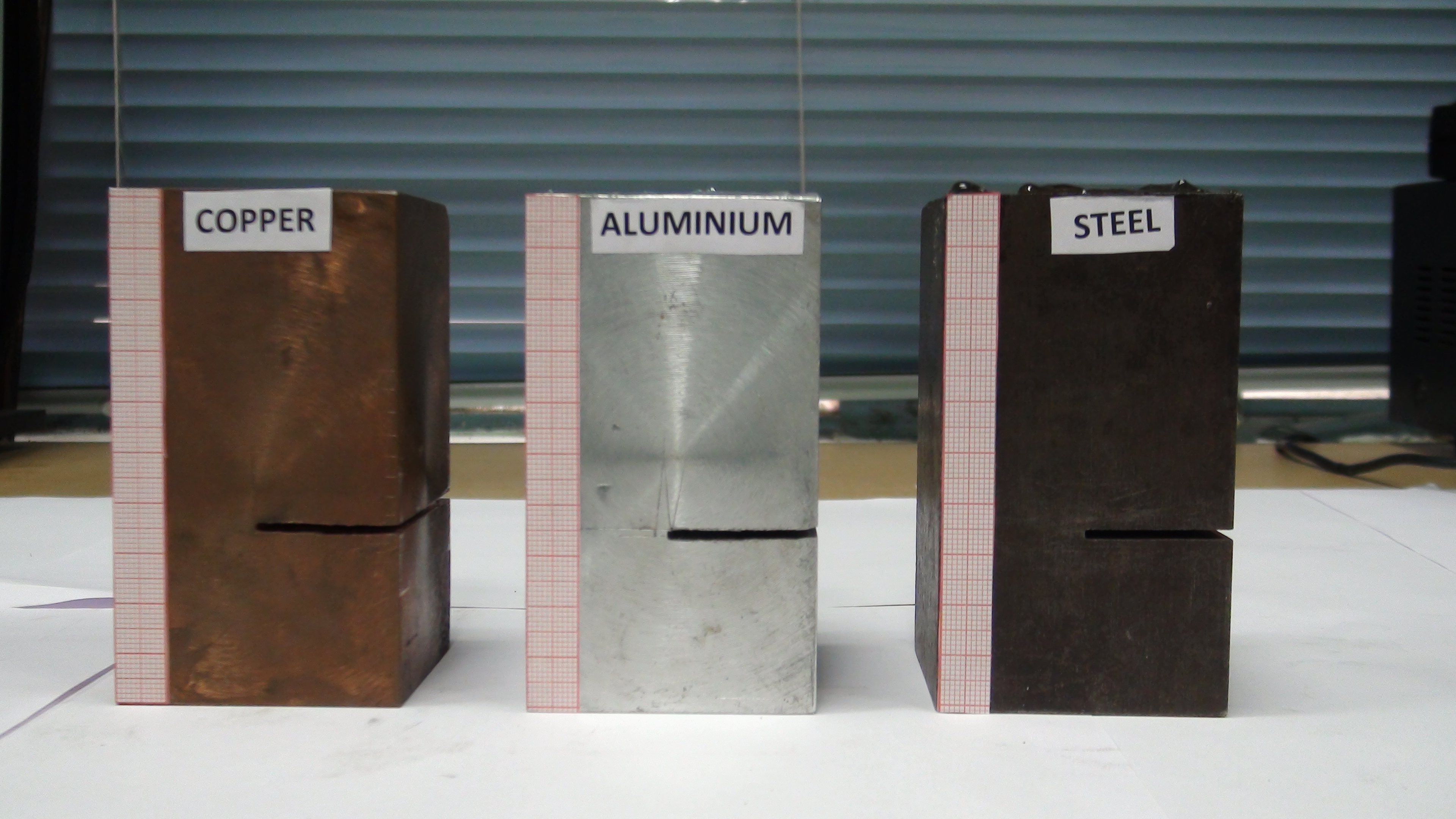

1. In this experiment three material (steel, copper, aluminium) blocks are taken under consideration.

2. These blocks of the materials are designed in the manner such that there is a cut in every block which is considered as fault in the material.

3. We spread the coupling agent at one end of the block.

4. The probe connected to the main machine is taken near the end of the block having the coupling agent in it. The Ultrasonics waves is being passed and the distance is measured from different positions of the block end.

5. If there is a difference found in measuring the distance from different points at the end of the material then we directly conclude that there is fault in the material.

6. Hence, fault in the material can be detected effectively using ultrasonics testing.